S11-M 6~10kV Oil immersed distribution transformer

| Rated

Capacity (kVA) |

Voltage combination and tap range |

Junction group label |

Load loss (W) |

Load loss (W) |

No-load

current (%) |

Short circuit impedance

(%) |

||

| (H.V.) | High voltage tap

range(%) |

(L.V.) | ||||||

| 30 |

11 10.5 10 6 |

±5 ±2×2.5% |

0.4 0.69 |

Dn |

100 | 630/600 | 2.3 | 4 |

| 50 | 130 | 910/870 | 2.0 | 4 | ||||

| 63 | 150 | 1090/1040 | 1.9 | 4 | ||||

| 80 | 180 | 1310/1250 | 1.9 | 4 | ||||

| 100 | 200 | 1580/1500 | 1.8 | 4 | ||||

| 125 | 240 | 1890/1800 | 1.7 | 4 | ||||

| 160 | 280 | 2310/2200 | 1.6 | 4 | ||||

| 200 | 340 | 2730/2600 | 1.5 | 4 | ||||

| 250 | 400 | 3200/3050 | 1.4 | 4 | ||||

| 315 | 480 | 3830/3650 | 1.4 | 4 | ||||

| 400 | 570 | 4520/4300 | 1.3 | 4 | ||||

| 500 | 680 | 5410/5150 | 1.2 | 4 | ||||

| 630 | 810 | 6200 | 1.1 | 4.5 | ||||

| 800 | 960 | 7500 | 1.0 | 4.5 | ||||

| 1000 | 1150 | 10300 | 1.0 | 4.5 | ||||

| 1250 | 1360 | 12000 | 0.9 | 4.5 | ||||

| 1600 | 1640 | 14500 | 0.8 | 4.5 | ||||

| 2000 | 1960 | 19800 | 0.8 | 5 | ||||

| 2500 | 2310 | 23000 | 0.7 | 5 | ||||

S11-M 20kV (30kVA~1600kVA Three-phase double winding non-excitation voltage regulating distribution transformer)

| Rated

Capacity (kVA) |

Voltage combination and tap range |

Junction group label |

Load loss (W) |

Load loss (W) |

No-load

current (%) |

Short circuit impedance

(%) |

||

| (H.V.) | High voltage tap

range(%) |

(L.V.) | ||||||

| 30 |

11 105 6 |

±5 ±2×2.5% |

0.4 0.69 |

bn |

100 | 630/600 | 2.3 | 4 |

| 50 | 130 | 910/870 | 2.0 | 4 | ||||

| 63 | 150 | 1090/1040 | 1.9 | 4 | ||||

| 80 | 180 | 1310/1250 | 1.9 | 4 | ||||

| 100 | 200 | 1580/1500 | 1.8 | 4 | ||||

| 125 | 240 | 1890/1800 | 1.7 | 4 | ||||

| 160 | 280 | 2310/2200 | 1.6 | 4 | ||||

| 200 | 340 | 2730/2600 | 1.5 | 4 | ||||

| 250 | 400 | 3200/3050 | 1.4 | 4 | ||||

| 315 | 480 | 3830/3650 | 1.4 | 4 | ||||

| 400 | 570 | 4520/4300 | 1.3 | 4 | ||||

| 500 | 680 | 5410/5150 | 1.2 | 4 | ||||

| 630 | 810 | 6200 | 1.1 | 4.5 | ||||

| 800 | 960 | 7500 | 1.0 | 4.5 | ||||

| 1000 | 1150 | 10300 | 1.0 | 4.5 | ||||

| 1250 | 1360 | 12000 | 0.9 | 4.5 | ||||

| 1600 | 1640 | 14500 | 0.8 | 4.5 | ||||

| 2000 | 1960 | 19800 | 0.8 | 5 | ||||

| 2500 | 2310 | 23000 | 0.7 | 5 | ||||

S13-M 6~10KVOil-immersed distribution transformer

| Rated

Capacity (kVA) |

Voltage combination and tap range | Junction group

label |

Load loss (W) |

Load loss (W) |

No-load

current (%) |

Short circuit

impedance (%) |

||

| (H.V.) | High voltage tap

range(%) |

(L.V.) | ||||||

| 30 |

6 6.3 6.6 10.5 11 |

±5 ±2×2.5% |

0.4 |

Dyn11 Yzn11 YynO |

80 | 630/600 | 1.8 | 4 |

| 50 | 100 | 910/870 | 1.6 | 4 | ||||

| 63 | 110 | 1090/1040 | 1.6 | 4 | ||||

| 80 | 130 | 1310/1250 | 1.5 | 4 | ||||

| 100 | 150 | 1580/1500 | 1.4 | 4 | ||||

| 125 | 170 | 1890/1800 | 1.4 | 4 | ||||

| 160 | 200 | 2310/2200 | 1.3 | 4 | ||||

| 200 | 240 | 2730/2600 | 1.2 | 4 | ||||

| 250 | 290 | 3200/3050 | 1.2 | 4 | ||||

| 315 | 340 | 3830/3650 | 1.1 | 4 | ||||

| 400 | 410 | 4520/4300 | 1.1 | 4 | ||||

| 500 | 480 | 5410/5150 | 1.0 | 4 | ||||

| 630 | 570 | 6200 | 0.9 | 4.5 | ||||

| 800 |

n |

700 | 7500 | 0.8 | 4.5 | |||

| 1000 | 830 | 10300 | 0.8 | 4.5 | ||||

| 1250 | 970 | 12000 | 0.7 | 4.5 | ||||

| 1600 | 1170 | 14500 | 0.6 | 4.5 | ||||

S13-M 20kV Oil-immersed distribution transformer

| Rated

Capacity (kVA) |

Junction group label |

Load loss (W) |

No-load

current (%) |

Short circuit

impedance (%) |

|||

| Voltage combination and tap range | |||||||

| (H.V.) | High voltage tap

range(%) |

(L.V.) | |||||

| 50 |

20 22 24 |

±5 ±2×2.5% |

0.4 |

Dyn11 YynO |

170 | 2.00 | 6.5 |

| 100 | 230 | 1.80 | 6.5 | ||||

| 125 | 270 | 1.70 | 6.5 | ||||

| 160 | 290 | 1.60 | 6.5 | ||||

| 200 | 340 | 1.50 | 6.5 | ||||

| 250 | 410 | 1.40 | 6.5 | ||||

| 315 | 490 | 1.40 | 6.5 | ||||

| 400 | 580 | 1.30 | 6.5 | ||||

| 500 | 690 | 1.20 | 6.5 | ||||

| 630 | 830 | 1.10 | 6.5 | ||||

| 800 | 980 | 1.00 | 6.5 | ||||

| 1000 | 1150 | 1.00 | 6.5 | ||||

| 1250 | 1410 | 0.90 | 6.5 | ||||

| 1600 | 1700 | 0.80 | 6.5 | ||||

Note:

1.The load loss above the dagona line in the table is applicable to the Dyn11 comecion group. The load loss value below the dagona line is applicable to the rymo connection group.

2.The performance parameters of other capacity products shall be determined by the user and the manufacturer.

Application:

S11,S13 series full-sealed oil-immersed transformers are suitable for power systems with AC 50Hz and rated working voltages of 20kV and below,as distribution transformers for petroleum, metallurgy, chemical, textile, light industry and other dusty places.

Features:

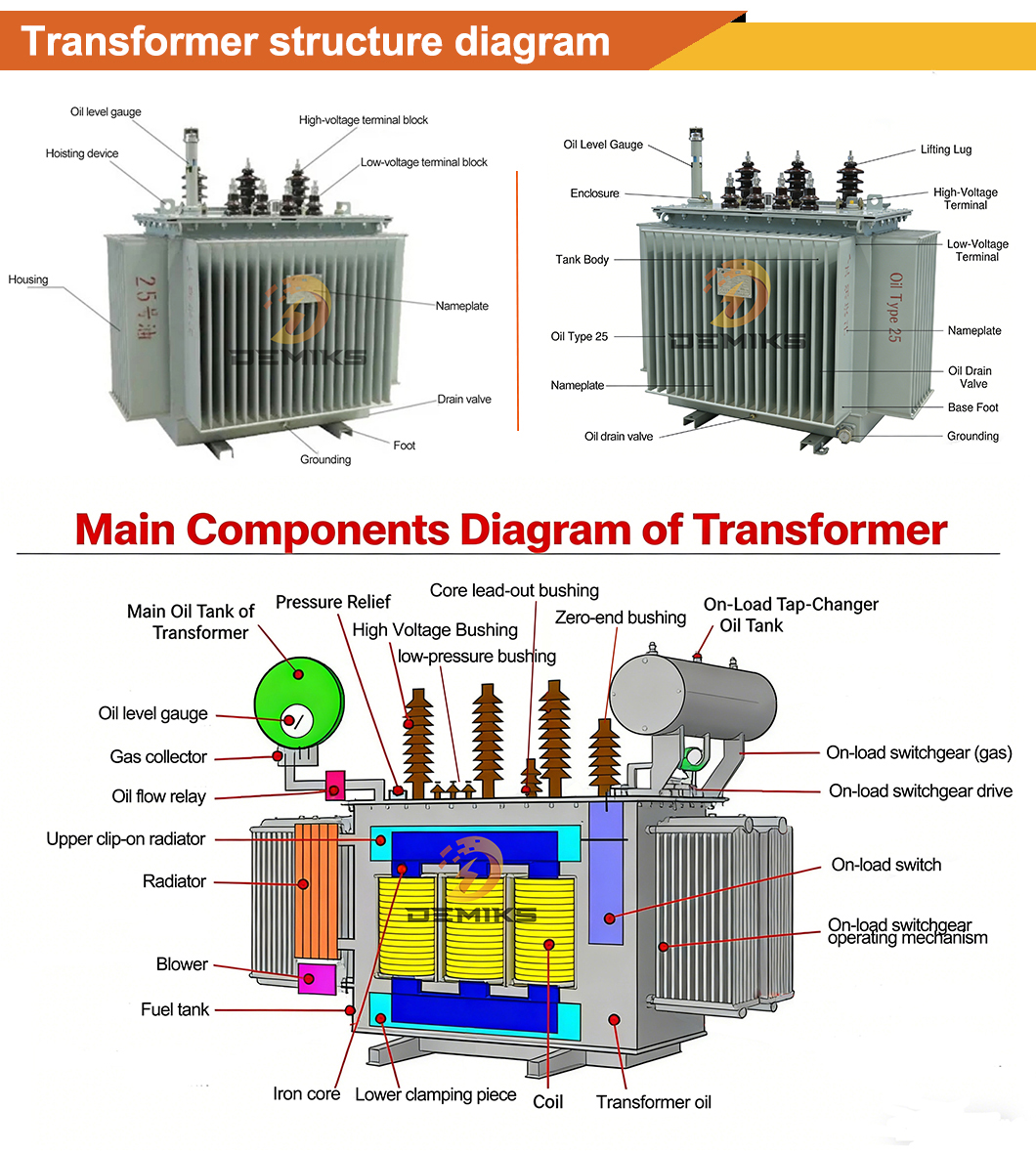

Iron core

The core is made of high permeability magnetic grain oriented cold rolled silicon steel sheet.The iron core is a new type of iron core,and the full oblique jointed iron core has a core section of a multi-stepped step,and the iron yoke and the iron core have equal sections.

Winding

The winding adopts corrugated oi passage,no immersion paint process,and the tightening belt is ted; the windings are concentric coils: the high-voltage winding has taps corresponding to the tapping voltage requirements,and is led to the tap changer, the switch is mounted on the box cover,and needs to be cut off.The tap voltage can be changed after the power supply.

Safety protection device

The 30-2000kVA transformer is equipped with a pressure relief valve;

A gas relay with an alarm and trip terminal can be installed according to user requirements; Oil temperature measuring device

The transformer is equipped with a tube holder of a glass thermometer,and the tube seat is arranged a the top of the oil tank and protrudes into the oil by 120±10 mm;

The 1000-2000kVA transformer is equipped with an outdoor signal thermometer;

Transformer tank

The transformer tank is composed of corrugated walls with dust on the surface.

Spray and paint film is firm.The corrugated fins not only have a cooling function,but also have a”breathing”function.The elasticity of the corrugated fins can compensate for the change in the volume of the transformer oil caused by the temperature rise and fall.Therefore,the fully sealed transformer has no oil storage cabinet,which reduces the over all height of the transformer;

The transformer is vacuum-filed during packaging,completely removing the moisture in the transformer,and the transformer oil is not in contact with the air.Effectively prevent oxygen and moisture from intruding into the transformer,resulting in a decrease in the insulation performance of the transformer and the possibility of aging of the transformer oi,so the oil sample test is performed irregularly;

We adhere to a market-oriented and customer-centric approach. In the highly competitive market, we have consistently earned the trust and recognition of our customers through exceptional product quality and efficient, comprehensive services.

Our solemn commitment to customers:Long-lasting Durability: We ensure that the service life of the supplied transformers is no less than 30 years.

Full-process Quality Control: From the receipt of bid documents, we initiate a comprehensive evaluation to ensure complete alignment with customer requirements. All raw materials and components are sourced from certified suppliers, and strict quality control standards are implemented. The production process strictly follows contracts and technical agreements, ensuring every step meets high-quality standards.

Hassle-free After-sales Service: All performance indicators of our transformers exceed or comply with national standards. Within three years after product installation and commissioning, if oil leakage occurs in oil-immersed transformers due to manufacturing reasons, we will provide free repairs. For any critical component issues arising during production or installation, we will prioritize project progress, address them promptly, and subsequently conduct responsibility analysis and corrective actions. We also sincerely welcome customers to visit our production site for supervision and guidance.

We provide comprehensive after-sales support, including free installation and commissioning guidance. After the product is put into operation, if any assistance is required, our service team will respond quickly:

24/7 Technical Support: We offer round-the-clock online support, including video calls, troubleshooting guides, and technical documentation, ensuring timely assistance for global customers.

Remote Diagnostic Services: Remote detection and diagnostics can be performed based on data provided by customers or through real-time video.

Regular Follow-up Mechanism: We have established a robust regular follow-up system to monitor product operation status online or on-site, ensuring customers can use our products with continuous peace of mind.

For complex issues, we will promptly dispatch experienced engineers to the site within the agreed international response time, providing services such as installation guidance, commissioning, maintenance, and repairs.

Dedicated Service RepresentativeEach customer is assigned a dedicated service representative who coordinates after-sales support, issue resolution, and regular follow-ups, ensuring seamless service throughout the entire process.

Continuous CareAfter installation, we conduct regular on-site or online follow-ups to continuously monitor product performance and promptly respond to customer feedback. Through proactive services, we ensure that equipment always operates at its optimal state, enhancing customer satisfaction.

By integrating rapid response, advanced technical support, and localized service experience, we have built a mature and efficient international service system. We are committed to providing professional and reliable after-sales support for global customers. We look forward to establishing long-term partnerships with you through continuous value delivery and high-quality services.

When purchasing an oil-immersed transformer, you may want to know the following questions & answers.

Pre-Sales FAQs

Q: What types of transformers do you supply?

A: We supply various transformers including Power Transformers, Distribution Transformers, Step-up/Step-down Transformers, Isolation Transformers, Auto-transformers, and Specialty Transformers (for applications like mining, marine, solar, etc.).

Q: Can you provide transformers according to my specific requirements?

A: Absolutely. We specialize in providing tailored solutions. You can specify parameters like power rating (kVA/MVA), input/output voltage, frequency (50Hz/60Hz), vector group, insulation class, cooling method, and standards (IEC, ANSI, IEEE, etc.). Our technical team will review and confirm the feasibility.

Q: What international standards do your transformers comply with?

A: Our transformers primarily comply with IEC standards. We can also provide products meeting ANSI/IEEE, CSA, EN, and other regional standards upon request. Please specify your required certification during inquiry.

Q: What are the common voltage and frequency ratings available?

A: We supply transformers for common global standards (e.g., 11kV, 33kV, 110kV, 220kV) and frequencies (50Hz or 60Hz). Custom combinations for specific markets are also available.

Q: How do I request a quote?

A: Please use our "Contact Us" form or email us directly with your detailed specifications, quantity, and destination port. The more details you provide, the more accurate our quotation will be.

Q: What are your payment terms?

A: Standard terms include T/T (Bank Transfer), 30% deposit with 70% before shipment. Other terms can be negotiated based on order value and relationship.

Q: Do you handle shipping and export documentation?

A: Yes, we are experienced in international trade. We can arrange FOB Shanghai, CIF, or other Incoterms as per your preference. We handle all export documentation including commercial invoice, packing list, bill of lading, certificate of origin, and test reports.

Q: What is your quality control process?

A: We work with certified manufacturers. Our quality control includes factory audits, material inspection, in-process monitoring, and final routine testing. Third-party inspection (SGS, BV, etc.) is welcome and can be arranged.

Q: Do you provide factory test reports?

A: Yes, standard routine test reports (as per IEC 60076) are provided with each shipment. Type tests and special tests can be arranged at the factory with prior notice.

Post-Sales FAQs

Q: What is your warranty policy?

A: We typically offer a standard warranty of 12 months from the date of commissioning or 18 months from the date of shipment, whichever comes first. The warranty covers manufacturing defects under normal operation as per agreed specifications.

Q: What should I do if I receive a damaged product or find a defect?

A: Contact our after-sales team immediately atdemikstransformer@gmail.com. Please provide your order number, photos, and a detailed description of the issue. We will guide you through the claim process and work swiftly to find a solution.

Q: What documents will I receive with the shipment?

A: You will receive a complete set of documents including user manual, wiring diagrams, test reports, certificates (of origin, compliance), and packing list.

Q: Can you provide on-site installation guidance or commissioning support?

A: While we provide detailed installation manuals, we can arrange remote guidance via video call. For complex projects, we can coordinate with the factory to provide on-site technician support at an additional cost.

Q: Do you provide maintenance advice for the transformers?

A: Yes, we provide basic operation and maintenance manuals. Key advice includes regular checks for oil level (for oil-immersed), temperature, unusual noise, and cleanliness. We recommend following local electrical safety regulations.

Q: Can I order spare parts from you?

A: Yes, we supply genuine spare parts like bushings, gauges, tap changers, gaskets, and sometimes cooling fans. Please provide your transformer model and serial number for accurate identification.

Q: Who should I contact for after-sales inquiries?

A: For any technical or service issues, please email our dedicated after-sales team at [Insert Email, e.g., demikstransformer@gmail.com or call +86 13916614261. Please have your order reference ready.

Q: What if I need a repair service not covered under warranty?

A: We offer full repair and refurbishment support. Contact us with the details, and we will provide a diagnostic and a competitive quotation for the repair service.