Dry Type Transformers: Working Principle, Diagrams, Parts, and Specifications

From power distribution networks in commercial buildings to sensitive industrial processes, dry type transformers are essential electrical components that provide safe and reliable voltage transformation. Unlike liquid-filled transformers, they use solid insulation and are valued for their enhanced safety, reduced environmental risk, and lower maintenance requirements. Understanding their design and operation is crucial for selecting the right transformer for your application.

This article provides a comprehensive technical analysis of dry type transformers, detailing their working principle, internal components, standard specifications, and typical applications to guide engineers and procurement specialists.

1. What is a Dry Type Transformer?

A dry type transformer is a voltage transformation device that uses high-grade solid insulation systems—such as vacuum pressure-impregnated (VPI) epoxy resin or cast resin—instead of liquid dielectric (oil or silicone fluid) to cool and insulate its core and windings. These transformers operate on the fundamental principle of electromagnetic induction, transferring electrical energy between circuits at different voltage levels.

Their defining characteristics are the absence of flammable liquids and a design focused on safety, durability, and environmental friendliness. This makes them the preferred choice for indoor installations where fire safety is paramount, including hospitals, schools, high-rise buildings, data centers, and industrial plants. Their self-extinguishing insulation materials significantly reduce fire hazards and eliminate the risk of soil or water contamination from fluid leaks.

2. Types of Dry Type Transformers

Dry type transformers are primarily categorized based on their insulation technology and cooling method. The two dominant types are Cast Resin Transformers and Vacuum Pressure Impregnated (VPI) Transformers.

2.1 Cast Resin Transformers (CRT)

In these transformers, the primary and secondary windings are encapsulated in a solid epoxy resin under vacuum. This process creates a windings block that is highly resistant to moisture, chemicals, and corrosive environments. CRTs are known for their exceptional mechanical strength and are ideal for harsh conditions like offshore platforms, chemical plants, and highly humid coastal areas.

2.2 Vacuum Pressure Impregnated (VPI) Transformers

Also known as “oven-cured” or “Varnished” transformers, VPI units use polyester, epoxy, or silicone varnish to impregnate the windings. The windings are first vacuum-dried and then impregnated with insulating varnish under pressure, followed by a curing cycle. This results in a robust, monolithic insulation system. VPI transformers are highly reliable for standard indoor commercial and industrial applications, offering a good balance of performance and cost.

A secondary classification is based on the transformer’s ability to withstand short-circuit stresses and its temperature rise class:

-

Standard Duty: For general power distribution.

-

High Efficiency / Low Loss: Designed to minimize no-load and load losses, often meeting premium efficiency standards (e.g., DOE 2016, IEC 60076-20-1).

-

Harmonic Mitigating: Specifically designed with special winding configurations (e.g., K-factor rated) to handle non-linear loads from modern electronic equipment without overheating.

-

Isolation Transformers: Provide electrical separation between primary and secondary circuits for safety or noise reduction.

3. Working Principle of a Dry Type Transformer

The operation of a dry type transformer is governed by the same core principle of electromagnetic induction as all transformers. There is no electrical connection between the primary (input) and secondary (output) windings. Instead, energy transfer occurs through a magnetic field.

3.1 Core Electromagnetic Process

-

AC Voltage Application: When an alternating current (AC) voltage (

V₁) is applied to the primary winding, it creates an alternating magnetic flux in the transformer’s high-grade silicon steel core. -

Flux Linkage: This alternating magnetic flux circulates through the closed low-reluctance magnetic core and links with the turns of both the primary and secondary windings.

-

EMF Induction: According to Faraday’s Law of Induction, the changing magnetic flux induces an electromotive force (EMF) in the secondary winding.

-

Voltage Transformation: The magnitude of the induced secondary voltage (

V₂) is directly proportional to the ratio of the number of turns in the secondary winding (N₂) to the number of turns in the primary winding (N₁). This is expressed by the fundamental transformer equation:

V₂ / V₁ = N₂ / N₁

IfN₂ > N₁, the voltage is stepped up. IfN₂ < N₁, the voltage is stepped down.

3.2 Heat Dissipation and Cooling

A key differentiator from oil-filled transformers is the cooling mechanism. Dry type transformers dissipate the heat generated by core (I²R) losses through convection and radiation.

-

Natural Air Cooling (AN): For lower ratings, heat is dissipated naturally into the surrounding air. The transformer’s enclosure is designed with ventilation openings to allow air to circulate.

-

Forced Air Cooling (AF): For higher ratings or to handle temporary overloads, fans are used to force air over the windings and core, significantly enhancing heat dissipation capacity. A transformer rated for 1000 kVA with AN cooling might be rated for 1300 kVA with AF cooling.

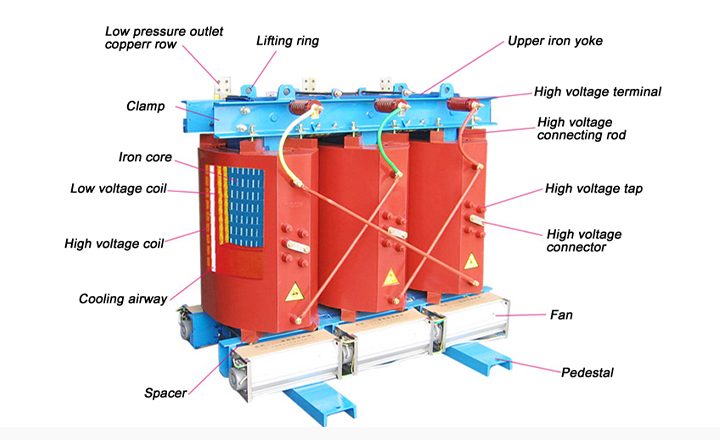

4. Dry Type Transformer Diagram

The following simplified cross-sectional diagram illustrates the key internal parts and the path of magnetic flux in a typical single-phase dry type transformer.

5. Key Parts of a Dry Type Transformer

The robust construction of a dry type transformer involves several critical components:

-

Magnetic Core: Constructed from cold-rolled, grain-oriented silicon steel laminations. These laminations are insulated from each other to minimize eddy current losses. The core provides a high-permeability path for the magnetic flux and is mechanically secured by core clamps and frames.

-

Windings (Copper or Aluminum): These are the current-carrying conductors wound around the core legs. HV and LV windings are concentrically arranged, with the LV winding typically placed closer to the core to reduce insulation requirements. The conductors are insulated with high-temperature materials like Nomex, glass, or polyester film.

-

Solid Insulation System: This is the defining component. For Cast Resin types, windings are fully encapsulated in epoxy resin. For VPI types, the insulation is a multi-layer system of polyester glass-backed mica tape, vacuum-impregnated with varnish. This system provides dielectric strength, mechanical support, and environmental protection.

-

Enclosure (Tank or Case): Provides mechanical protection and supports internal components. It is typically made of galvanized steel or aluminum and includes ventilation grilles or ducts (for AN/AF cooling) or may be sealed for certain environments. Enclosures often have an IP (Ingress Protection) rating (e.g., IP23) to define their level of protection against solid objects and water.

-

Terminals and Bushings: Provide the external electrical connection points for incoming (primary) and outgoing (secondary) cables. They are designed for safe, reliable connections and are clearly marked.

-

Cooling System: Consists of ventilation ducts within the windings and core for natural airflow. For AF rating, it includes thermostatically controlled axial fans mounted to direct air over the hottest parts.

-

Monitoring and Protection Devices (Optional):

-

Temperature Sensors (PT100/PTC): Embedded in the windings to monitor hotspot temperature and provide alarm/trip signals or control cooling fans.

-

Surge Arresters: Protect against voltage spikes.

-

Terminal Shields: Provide additional safety by covering live terminals.

-

6. Dry Type Transformer Specifications

Selecting a dry type transformer requires careful review of technical specifications. Key parameters are outlined in the table below and detailed thereafter.

| Specification Category | Typical Parameters & Standard Values | Importance / Implication |

|---|---|---|

| Power Rating | 50 kVA, 100 kVA, 500 kVA, 1000 kVA, 2500 kVA | Defines the continuous load-carrying capacity under specified conditions. |

| Voltage Ratings (Primary & Secondary) |

HV: 11kV, 13.8kV, 33kV LV: 415V, 480V, 600V |

Must match the system voltage. Taps (e.g., ±2×2.5%) allow adjustment for varying input voltage. |

| Insulation Class / Temperature Rise |

Class B (130°C): 80°C rise Class F (155°C): 100°C rise Class H (180°C): 125°C rise |

Determines maximum operating temperature. A lower temperature rise (e.g., 80°C) indicates higher efficiency and longer life. |

| Impedance (%) | 4%, 5%, 6%, 8% (Common for LV) Higher for special applications |

Limits short-circuit current. System studies determine the required value for proper protective device coordination. |

| Efficiency Standard | DOE 2016 (USA), IEC 60076-20-1, CSA C802.2 | Mandates minimum efficiency levels at various loads (25%, 50%, 75%, 100%). “Premium Efficiency” models exceed standard minimums. |

| Sound Level (dB(A)) | 55 dB(A), 60 dB(A), 65 dB(A) | Critical for installations near offices or residential areas. Measured at 1 meter under no-load conditions. |

| Enclosure & Protection (IP Code) |

IP00 (Open), IP23 (Protected against water spray), IP54 (Dust & water protected) | IP23 is standard for indoor use. IP54 or higher is needed for harsh/dusty environments. |

| Standards Compliance | IEC 60076-11, IEEE C57.12.01, UL 5085, EN 61558 | Certifies design, testing, and safety compliance for the target market. |

| Connections | Delta (Δ) or Wye (Y) | HV and LV winding connection configurations must suit the system (e.g., Delta-Wye is common for step-down). |

6.1 Detailed Specification Considerations:

-

Losses: Total losses comprise No-Load Loss (Core Loss) and Load Loss (Copper Loss). High-efficiency transformers have lower losses, resulting in significant energy cost savings over the transformer’s lifetime.

-

Overload Capacity: Dry type transformers typically have good short-term overload capability (e.g., 120% load for 2 hours, 150% load for 30 minutes) as defined by standards like IEC 60076-12.

-

Harmonic Loads: For loads with significant harmonics (e.g., from VFDs, UPS systems), a K-rated transformer (e.g., K-13) or a transformer with de-rated capacity or higher temperature class (e.g., Class H instead of Class F) is required.

-

Seismic Withstand: For installations in earthquake-prone zones, a seismic qualification (e.g., IBC, IEEE 693) specifying a seismic zone or acceleration level (0.5g, 1.0g) is essential.

6.2 Factors to Consider When Specifying a Dry Type Transformer

Choosing the correct dry type transformer ensures reliability, efficiency, and safety. The decision matrix from the referenced source, adapted for transformers, highlights key considerations:

| Application / Need Factor | Recommended Priority | Key Rationale |

|---|---|---|

| Indoor Public/Confined Spaces (Schools, Hospitals, High-rises) |

Highest Priority | Fire safety is non-negotiable. Dry types eliminate flammable fluid risk and are often mandated by building codes. |

| High Efficiency / Low Lifetime Cost | High Priority | Premium efficiency (e.g., IE4) models have higher upfront cost but offer the fastest payback through energy savings, especially for 24/7 operations. |

| Harsh/Dusty Environments (Mines, Industrial Plants) |

High Priority | Requires encapsulated (Cast Resin) design and a high IP-rated enclosure (IP54 or higher) for immunity to moisture and contaminants. |

| Non-Linear/Harmonic Loads (Data Centers, Manufacturing) |

High Priority | Must specify a transformer with appropriate K-rating or with de-rated capacity to prevent overheating from harmonic currents. |

| Temporary/Portable Installations | Medium Priority | Lightweight aluminum-wound units or compact designs offer easier transport and installation. |

| Low Initial Capital Cost | Medium Priority | Standard-efficiency VPI transformers offer a reliable, cost-effective solution for basic power distribution with normal loads. |

| Extremely Quiet Operation | Specific Need | Requires specifying a low sound level (e.g., <55 dB(A)) model, which may involve special core/winding construction. |

Conclusion

Dry type transformers represent a critical, safe, and versatile solution for modern electrical power distribution. Their solid insulation technology makes them indispensable for indoor and safety-conscious applications, while advancements in materials and design continue to improve their efficiency and power density.

Selecting the right transformer involves a careful balance of technical specifications—power rating, voltage, insulation class, impedance, and efficiency—against the specific demands of the application, whether it’s a clean office building, a harmonic-rich data center, or a corrosive industrial plant. By understanding the working principles, components, and key specifications detailed in this guide, engineers and facility managers can make informed decisions that ensure reliable, efficient, and safe power system operation for decades.