Research on Key Technologies and Applications in the Design and Manufacturing of Large Medium and High Voltage Transformers

summary

With the rapid development of my country’s power industry and the advancement of national strategies such as the construction of ultra-high voltage power grids, the integration of new energy sources, the upgrading of large-scale industries, and the acceleration of rail transit, the demand for large medium- and high-voltage transformers continues to rise. At the same time, more stringent requirements are being placed on their reliability, energy efficiency, intelligence, and customization. As core hub equipment in the power system, large medium- and high-voltage transformers undertake the critical functions of voltage transformation, energy transmission, and distribution. Their design and manufacturing level directly determines the power supply stability, operating efficiency, and safety and reliability of the power system. This paper takes large medium- and high-voltage transformers (high-voltage side voltage ≥35kV, rated capacity ≥10000kVA) as the research object, systematically reviews the development background and current status of the industry, deeply studies their core design technologies, key manufacturing processes, and performance testing and verification methods, analyzes the technological implementation effects with engineering application cases, and discusses the current problems in technological development and future improvement directions. The aim is to provide theoretical support and practical reference for the design optimization, manufacturing upgrade, and engineering application of large medium- and high-voltage transformers, and to promote the development of my country’s large medium- and high-voltage transformer industry towards high-end, intelligent, and green directions.

Keywords: Large medium and high voltage transformers; design technology; manufacturing process; performance testing; engineering applications

1.Introduction

1.1 Research Background

Electricity is a fundamental energy source for national economic development, and the safe and stable operation of the power system is directly related to the normal order of social production and life. With the introduction of my country’s “dual carbon” target, the new energy industry (photovoltaics, wind power, energy storage, etc.) has experienced explosive growth, the construction of ultra-high voltage power grids has been accelerated, large-scale industrial enterprises (metallurgy, chemical, steel, etc.) are upgrading on a large scale, and the rapid development of rail transit, super-large buildings, and other fields have led to a continuous increase in the transmission capacity and transmission distance of the power system, which in turn raises the performance requirements for power hub equipment.

Large medium- and high-voltage transformers, as core equipment for voltage transformation and energy transmission in power systems, are widely used in key scenarios such as step-up/step-down substations in the main power grid, grid connection of large-scale new energy power plants, power supply for large industrial plants and mines, and power distribution in rail transit hubs and ultra-large buildings. Compared with ordinary low-voltage distribution transformers, large medium- and high-voltage transformers are characterized by high voltage levels, large rated capacity, complex structures, and harsh operating conditions. Their operational reliability directly affects the stability of regional power supply. Once a failure occurs, it may cause large-scale power outages, resulting in huge economic losses and social impacts.

In recent years, the rapid development of my country’s power industry has spurred the rise of the large-scale medium and high-voltage transformer industry. Domestic transformer manufacturers have continuously increased their investment in technological research and development, gradually breaking through a series of core technological bottlenecks, improving product performance, and expanding production capacity. However, at the same time, facing the harmonic pollution and high overload requirements brought about by the grid connection of new energy sources, the high insulation and strong short-circuit withstand requirements brought about by ultra-high-voltage power transmission, and the energy conservation and emission reduction requirements under the “dual carbon” target, my country’s large-scale medium and high-voltage transformers still lag behind international advanced levels in terms of design concepts, core technologies, manufacturing processes, and intelligentization. Some high-end core components still rely on imports, and the level of technological self-reliance needs to be further improved.

Against this backdrop, systematically conducting research on key technologies and applications in the design and manufacturing of large medium and high voltage transformers, breaking through technical bottlenecks, optimizing product design, and improving manufacturing processes are of significant practical and strategic importance for ensuring the safe and stable operation of the power system, promoting the development of the new energy industry, and achieving the “dual carbon” goal.

1.2 Significance of the Research

1.2.1 Theoretical Significance

This paper systematically reviews the design theory and manufacturing process of large medium- and high-voltage transformers, deeply studies the design optimization methods of core components such as core, windings, insulation, and cooling, analyzes the key quality control points of critical processes in manufacturing, and establishes a performance testing and verification system, thus enriching the theoretical research system of large medium- and high-voltage transformers. Furthermore, addressing the specific requirements of emerging application scenarios such as new energy grid connection and ultra-high-voltage power transmission, targeted design optimization schemes and process improvement measures are proposed, providing new ideas and directions for theoretical innovation in large medium- and high-voltage transformers and promoting technological progress in the transformer field.

1.2.2 Engineering Significance

The research findings in this paper can be directly applied to the design and manufacturing practice of large, medium, and high-voltage transformers. By optimizing product design and improving manufacturing processes, the operational reliability, energy efficiency, and intelligence level of transformers can be effectively improved, while reducing product failure rates and maintenance costs. Furthermore, this paper, combined with engineering application cases, verifies the feasibility and effectiveness of the design and manufacturing technologies, providing practical reference for domestic transformer manufacturers. This will help promote the development of my country’s large, medium, and high-voltage transformer industry towards high-end, intelligent, and green directions, enhance the international competitiveness of Chinese transformer products, break the international technological monopoly on high-end products, and ensure the independent controllability of my country’s power equipment.

1.3 Current Status of Research at Home and Abroad

1.3.1 Current Status of International Research

Research on large medium and high voltage transformers started earlier abroad. After decades of development, a technology system with internationally renowned companies such as Siemens, ABB, Toshiba, and Mitsubishi as the core has been formed, and they are in a leading position in terms of design concepts, core technologies, manufacturing processes, and intelligentization.

In terms of design technology, foreign companies generally employ advanced design tools such as 3D modeling and finite element analysis to achieve refined design of core components like transformer cores, windings, and insulation. This allows for precise simulation of the electromagnetic, temperature, and flow field distributions of the transformer, optimizing product structure and improving performance. Simultaneously, for special scenarios such as new energy grid connection and ultra-high voltage transmission, foreign companies have developed specialized large-scale medium- and high-voltage transformers, such as high-overload, low-loss, and harmonic-resistant new energy-specific transformers, meeting the personalized needs of different scenarios. Regarding insulation design, foreign companies utilize new insulation materials and advanced insulation structure designs, improving the insulation performance and service life of transformers, enabling them to withstand harsh operating conditions such as high voltage, high humidity, and high altitude.

In terms of manufacturing processes, foreign companies have achieved automated and intelligent production of core processes, such as core stacking, winding, vacuum drying, and vacuum oil injection, all using automated equipment, which has improved production efficiency and product quality stability. Simultaneously, foreign companies have established comprehensive quality control systems, achieving end-to-end quality control from raw material procurement and production process management to product testing, ensuring product reliability. Regarding the manufacturing of core components, foreign companies possess mature technological systems and are capable of independently producing high-grade silicon steel sheets, oxygen-free copper rods, and new insulating materials, ensuring technological independence for their products.

In terms of intelligent technology, foreign companies have deeply integrated advanced technologies such as the Internet of Things, big data, and artificial intelligence with transformer products, developing intelligent monitoring systems that can monitor transformer operating parameters such as oil temperature, oil level, partial discharge, and core grounding current in real time. This enables fault early warning and condition-based maintenance, improving the level of intelligent operation and maintenance of transformers. Simultaneously, foreign companies are also promoting lightweight and miniaturized transformer designs, reducing transportation costs and installation difficulties.

1.3.2 Current Status of Domestic Research

Research on large medium and high voltage transformers in my country began in the 1960s. After decades of development, especially the rapid development in recent years, my country’s transformer industry has achieved remarkable results and has gradually formed an industrial cluster with companies such as TBEA, Baobian Electric, and West-to-East Power Transmission as its core. Its products cover multiple voltage levels from 35kV to 1000kV, with rated capacities ranging from 10,000kVA to millions of kVA, which can meet the application needs of different scenarios.

In terms of design technology, domestic enterprises have gradually introduced advanced design tools such as 3D modeling and finite element analysis, enabling refined design of core transformer components and continuous improvement in product performance. Simultaneously, domestic enterprises have conducted research and development on specialized transformers for special scenarios such as new energy grid connection and ultra-high voltage transmission, including dedicated transformers for photovoltaic/wind power grid connection and ultra-high voltage step-down transformers, with some products achieving internationally advanced performance levels. Regarding insulation design, domestic enterprises have conducted applied research on new insulation materials, adopting novel insulation materials such as epoxy casting and Nomex paper, improving the insulation performance and service life of transformers.

In terms of manufacturing processes, domestic enterprises have continuously increased investment in technological transformation, promoting the automation and intelligent upgrading of core processes. For example, processes such as core stacking and winding have gradually achieved automated production, while processes like vacuum drying and vacuum oil injection have been continuously optimized, significantly improving production efficiency and product quality stability. Simultaneously, domestic enterprises have established a comprehensive quality control system, strengthening quality control during production and continuously improving product reliability. Regarding the manufacturing of core components, domestic enterprises have gradually overcome technological bottlenecks in high-grade silicon steel sheets and oxygen-free copper rods, achieving independent production of some core components. However, they still rely on imports for new insulation materials and high-end monitoring equipment, and the level of technological self-reliance needs further improvement.

In terms of intelligentization, domestic enterprises have actively promoted the intelligent upgrading of transformers, developed intelligent monitoring systems, and achieved real-time monitoring of transformer operating parameters and fault early warning. Some enterprises have also carried out research on intelligent operation and maintenance technologies, promoting the transformation and upgrading of transformer operation and maintenance models. At the same time, domestic enterprises have achieved remarkable results in energy conservation and consumption reduction of transformers, developing large medium and high voltage transformers with first-class energy efficiency and super-first-class energy efficiency, meeting the energy conservation requirements under the “dual carbon” target.

Despite the remarkable achievements of my country’s large-scale medium and high-voltage transformer industry, there are still some gaps compared with international advanced levels. These gaps are mainly reflected in the following aspects: First, the design concepts are still relatively traditional, the level of refined design needs to be improved, and the analysis of electromagnetic, temperature, and flow field coupling under complex working conditions is not in-depth enough. Second, there are still shortcomings in core manufacturing processes, the automation and intelligence levels of some key processes are not high, and the stability of product quality needs to be further improved. Third, the level of self-sufficiency in core component technology is insufficient, and new insulation materials and high-end monitoring equipment still rely on imports. Fourth, the level of intelligence is still in its early stages, and the integrated application of technologies such as intelligent monitoring, fault diagnosis, and condition-based maintenance is not mature enough.

1.4 Research Content and Methods

1.4.1 Research Content

This paper takes large medium- and high-voltage transformers as the research object, and conducts in-depth research on their key design and manufacturing technologies and applications. The specific research contents are as follows:

- Theoretical Foundation Research on Large Medium and High Voltage Transformers: This research outlines the basic structure and working principle of large medium and high voltage transformers, clarifies their core performance indicators, and analyzes their operating conditions and special requirements, laying a theoretical foundation for subsequent design and manufacturing technology research.

- Research on core design technologies of large medium and high voltage transformers: Focusing on the design technologies of core, winding, insulation and cooling systems, analyzing key influencing factors in the design process, proposing targeted design optimization schemes to improve transformer performance and control costs.

- Research on key manufacturing processes of large medium and high voltage transformers: This study investigates the key process points of critical manufacturing steps such as core stacking, winding, vacuum drying, vacuum oil injection, and tank welding, analyzes the quality control difficulties in the manufacturing process, proposes process optimization measures, and improves product quality stability.

- Performance Test Verification Research of Large Medium and High Voltage Transformers: Review the core performance test items of large medium and high voltage transformers, study the test principles, test methods and test equipment, establish a performance test verification system, and verify the feasibility and effectiveness of the design and manufacturing technology through tests.

- Case Study Analysis of Large Medium and High Voltage Transformer Engineering Applications: Based on specific engineering application cases, this paper analyzes the design and manufacturing schemes and operational effects of large medium and high voltage transformers, summarizes technical application experience, and verifies the practicality of the research results.

- Research on the problems and improvement directions in the development of large medium and high voltage transformer technology: This study analyzes the current problems in the design and manufacturing technology of large medium and high voltage transformers in my country, and proposes targeted improvement directions and development suggestions in combination with industry development trends to promote industrial upgrading.

1.4.2 Research Methods

This paper employs a research methodology that combines theoretical and practical research, as well as qualitative and quantitative analysis, as detailed below:

- Literature review method: By reviewing relevant domestic and international literature, journals, patents and industry reports, we sorted out the research status, core technologies and development trends of large medium and high voltage transformers, and drew on advanced research results at home and abroad to provide theoretical support and ideas for this study.

- Theoretical Analysis Method: Based on relevant theories such as electromagnetics, heat transfer, and materials science, this method analyzes the working principle, design and manufacturing rules of large medium and high voltage transformers, establishes relevant mathematical models, quantitatively analyzes key parameters in the design and manufacturing process, and proposes design optimization schemes and process improvement measures.

- Experimental research method: By conducting performance tests on large medium and high voltage transformers, including insulation tests, DC resistance tests, turns ratio tests, temperature rise tests, and partial discharge tests, the feasibility and effectiveness of the design and manufacturing technology are verified, and test data is obtained to provide data support for design optimization and process improvement.

- Case Study Method: By combining specific engineering application cases, analyze the design and manufacturing schemes and operational effects of large medium and high voltage transformers, summarize technical application experience, and verify the practicality and applicability of research results.

- Comparative Analysis Method: Compare the design and manufacturing technologies and product performance of large medium and high voltage transformers at home and abroad, analyze the gap between my country and the international advanced level, and propose targeted improvement directions and development suggestions.

1.5 Paper Structure and Innovation Points

1.5.1 Paper Structure

This article is divided into 8 chapters, and the specific structure is as follows:

Chapter 1 Introduction: This chapter elaborates on the research background, significance, current research status at home and abroad, research content and methods, paper structure and innovative points, and clarifies the research ideas and focus of this paper.

Chapter 2: Theoretical Foundations of Large Medium and High Voltage Transformers: This chapter outlines the basic structure and working principle of large medium and high voltage transformers, clarifies core performance indicators, analyzes operating conditions and special requirements, and lays the theoretical foundation.

Chapter 3 Research on Core Design Technologies of Large Medium and High Voltage Transformers: This chapter focuses on the design technologies of the core, windings, insulation, and cooling systems, and proposes design optimization schemes.

Chapter 4 Research on Key Manufacturing Processes of Large Medium and High Voltage Transformers: This chapter studies the key process points of critical manufacturing procedures and proposes process optimization measures and quality control methods.

Chapter 5 Performance Test Verification Research of Large Medium and High Voltage Transformers: This chapter reviews the test items, studies the test methods, establishes a test verification system, and verifies the research results through tests.

Chapter 6: Case Studies of Large Medium and High Voltage Transformer Engineering Applications: This chapter analyzes the effects of technology application and summarizes experiences through specific case studies.

Chapter 7 Problems and Improvement Directions in the Development of Large Medium and High Voltage Transformer Technology: This chapter analyzes the current problems and proposes improvement directions and development suggestions.

Chapter 8 Conclusion and Outlook: This chapter summarizes the research findings of this paper and looks forward to future research directions.

1.5.2 The paper’s innovative points

The innovations of this paper are mainly reflected in the following aspects:

- A collaborative optimization design method for the core and windings of large medium and high voltage transformers is proposed. By combining finite element analysis technology, the electromagnetic field distribution is accurately simulated, and the core stacking method and winding structure are optimized. While improving the transformer’s short-circuit withstand capability and reducing losses, the cost is effectively controlled, solving the problem of balancing performance and cost in traditional designs.

- To address the challenges in quality control of the vacuum oil injection process for large medium and high voltage transformers, a process optimization scheme based on the coordinated control of oil temperature, oil level, and vacuum degree was proposed. This scheme optimized the oil injection process and parameter settings, effectively reducing residual air bubbles inside the transformer and improving insulation performance and operational reliability.

- In light of the special requirements for grid connection of new energy sources, a new design scheme for large medium and high voltage transformers with anti-harmonic and high overload capabilities was proposed. The winding structure and insulation design were optimized, which improved the transformer’s tolerance to harmonic pollution and overload operation capability, making it suitable for the complex operating conditions of new energy power plants.

- A full life-cycle quality control system for large medium and high voltage transformers has been established, which includes all aspects such as design, manufacturing, testing, operation and maintenance. Combined with intelligent monitoring technology, the system enables full-process traceability of transformer quality and early warning of faults, thereby improving the level of intelligent operation and maintenance of transformers.

2.Theoretical Basis of Large Medium and High Voltage Transformers

2.1 Basic Structure and Working Principle of Large Medium and High Voltage Transformers

2.1.1 Basic Structure

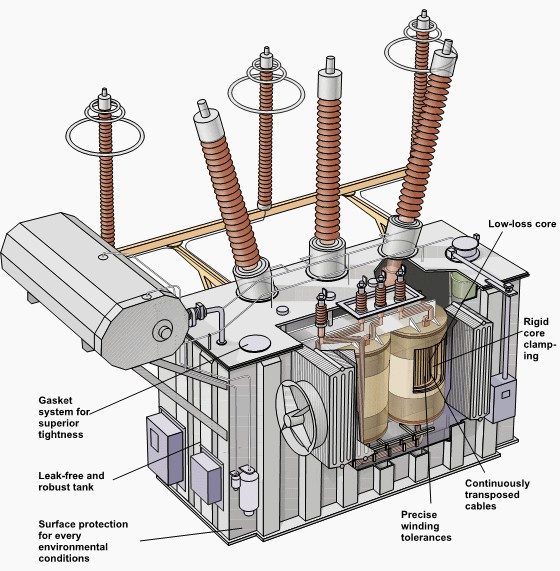

Large medium- and high-voltage transformers have complex structures, mainly composed of iron core, windings, insulation system, cooling system, oil tank, leads, and accessories. These parts work together to achieve voltage transformation and energy transmission. A schematic diagram of its core structure is shown in Figure 2-1 (figures are omitted here; they can be added in the actual paper).

- Core: The core is the magnetic circuit core of a large, medium, and high-voltage transformer. Its main function is to conduct magnetic flux and realize the conversion of electromagnetic energy. The cores of large, medium, and high-voltage transformers are mostly made of high-grade grain-oriented silicon steel sheets stacked together. Based on their structure, they can be divided into core-type cores and shell-type cores. Core-type cores are widely used in large, medium, and high-voltage transformers due to their compact structure, ease of manufacturing, and good heat dissipation. A core-type core mainly consists of core columns, a yoke, and clamping devices. Windings are fitted onto the core columns, the yoke connects the core columns to form a closed magnetic circuit, and the clamping devices fix the core to prevent vibration and deformation.

- Windings: Windings are the core of the circuit of large medium and high voltage transformers. Their main function is to generate a magnetic field through current to achieve voltage transformation. The windings of large medium and high voltage transformers are mostly made of oxygen-free copper or aluminum rods. According to their structural form, they can be divided into layered windings, disc windings, intertwined windings, and continuous windings. Among these, intertwined and continuous windings are widely used in medium and high voltage windings due to their good insulation performance and strong short-circuit withstand capability. The windings are divided into high-voltage windings and low-voltage windings. According to their arrangement, they can be divided into concentric windings and overlapping windings. Concentric windings are the most widely used due to their simple structure and ease of manufacturing. The high-voltage winding is arranged on the outside, and the low-voltage winding is arranged on the inside, with an insulation gap between them to ensure insulation performance.

- Insulation System: The insulation system is a crucial component of large, medium, and high-voltage transformers. Its main function is to isolate components at different potentials, prevent insulation breakdown, and ensure the safe operation of the transformer. The insulation system of large, medium, and high-voltage transformers is divided into internal insulation and external insulation. Internal insulation mainly includes winding insulation, core insulation, and lead wire insulation, while external insulation mainly includes bushing insulation and tank insulation. Internal insulation often uses insulating paper, insulating oil, and epoxy resin casting materials, while external insulation often uses porcelain bushings and composite bushings.

- Cooling System: The main function of the cooling system is to dissipate the heat generated during transformer operation, preventing damage due to overheating and ensuring normal operation. Large medium and high voltage transformers have significant losses and generate a large amount of heat, thus requiring a highly efficient cooling system. Commonly used cooling methods include oil-immersed self-cooling (ONAN), oil-immersed air cooling (OFAF), forced oil circulation air cooling (OFAF), and forced oil circulation water cooling (OFPW). Among these, forced oil circulation air cooling and forced oil circulation water cooling are widely used in large medium and high voltage transformers due to their high cooling efficiency. The cooling system mainly consists of radiators, cooling fans, oil pumps, oil pipes, and temperature control devices.

- Oil Tank: The oil tank is the outer shell of a large medium- and high-voltage transformer. Its main function is to contain insulating oil and protect internal components, while also providing some heat dissipation. Oil tanks of large medium- and high-voltage transformers are mostly welded from steel plates. Based on their structure, they can be divided into bell-type oil tanks and barrel-type oil tanks. Bell-type oil tanks are widely used in large medium- and high-voltage transformers due to their ease of maintenance. The oil tank is equipped with accessories such as an oil conservator, oil level gauge, oil temperature gauge, gas relay, and drain valve to ensure the normal operation and maintenance of the oil tank.

- Leads and Accessories: The main function of leads is to connect the windings to the external circuit and transmit current. Leads in large medium and high voltage transformers are mostly made of copper or aluminum busbars, with different cross-sectional dimensions and insulation structures depending on the voltage level and current. Accessories include bushings, gas relays, pressure relief valves, oil conservators, oil level gauges, and oil temperature gauges. These accessories are essential components for ensuring the normal operation and maintenance of the transformer.

2.1.2 Working Principle

The working principle of large medium and high voltage transformers is based on the law of electromagnetic induction, specifically including mutual inductance and the principle of electromagnetic induction. The transformer core has two windings with different numbers of turns: a primary winding (high-voltage winding) and a secondary winding (low-voltage winding). When the primary winding is connected to an AC power source, an alternating current is generated. This alternating current generates an alternating magnetic field through the winding, which is then conducted to the secondary winding through the core. According to the law of electromagnetic induction, an induced electromotive force is generated in the secondary winding, thereby achieving voltage transformation.

According to the law of electromagnetic induction, the voltage ratio of a transformer is directly proportional to the turns ratio, and the current ratio is inversely proportional to the turns ratio. The basic formula is as follows:

Wherein, is the rated voltage of the primary winding, is the rated voltage of the secondary winding, is the number of turns of the primary winding, is the number of turns of the secondary winding, is the transformer turns ratio, is the rated current of the primary winding, and is the rated current of the secondary winding.

Ideally, the input power of a transformer equals its output power, i.e. , the input power equals the output power. However, in actual operation, transformers will generate certain losses, including copper losses and iron losses. Therefore, the input power is greater than the output power, and the efficiency of a transformer is the ratio of the output power to the input power.

In addition to voltage transformation and energy transmission, large medium and high voltage transformers need to withstand various operating conditions such as grid voltage fluctuations, short-circuit currents, and harmonic pollution during operation. Therefore, they need to have good insulation performance, short-circuit withstand capability, harmonic withstand capability, and heat dissipation performance to ensure their safe and stable operation.

2.2 Core Performance Indicators of Large Medium and High Voltage Transformers

The core performance indicators of large medium- and high-voltage transformers directly determine their operational reliability, energy efficiency, and applicability. They are the core control objectives in the design and manufacturing process and an important basis for user selection. Considering the operating conditions and application requirements of large medium- and high-voltage transformers, their core performance indicators mainly include the following aspects:

2.2.1 Voltage Level and Rated Capacity

Voltage level and rated capacity are the most basic performance indicators of large medium and high voltage transformers, which directly determine the application scenarios and power transmission capacity of the transformer.

- Voltage Level: The voltage level of large medium and high voltage transformers mainly refers to the rated voltage on the high-voltage side. According to my country’s power industry standards, the voltage levels of large medium and high voltage transformers mainly include 35kV, 66kV, 110kV, 220kV, 330kV, and 500kV, among which 35kV~220kV is the medium and high voltage range, and 330kV and above is the ultra-high voltage range. The selection of voltage level is mainly determined by the power transmission requirements of the application scenario and the grid voltage level. For example, the main power grid often uses a voltage level of 110kV~500kV, large industrial plants and mines often use a voltage level of 35kV~110kV, and new energy power plants often use a voltage level of 35kV~66kV for grid connection.

- Rated Capacity: Rated capacity refers to the maximum output power that a transformer can continuously output under rated voltage and frequency, measured in kVA or MVA. The rated capacity of large medium and high voltage transformers is typically ≥10000kVA, with a common range of 10000kVA to 500000kVA. Transformers at voltage levels of 110kV to 220kV often have a capacity ≥31500kVA. The selection of rated capacity is primarily based on the load requirements of the application scenario, taking into account factors such as the rated power of the load, the load growth rate, and overload requirements to ensure that the transformer can meet actual operating needs.

2.2.2 Losses and Efficiency

Losses and efficiency are important energy-saving performance indicators for large, medium, and high-voltage transformers, directly affecting their operating costs and the achievement of “dual carbon” targets. Losses in large, medium, and high-voltage transformers mainly include copper losses and iron losses, while efficiency is the ratio of output power to input power.

- Copper Loss: Copper loss, also known as load loss, refers to the loss generated when current flows through the windings of a transformer during operation. It is mainly determined by the winding resistance and the square of the current, as shown in the formula: , where is the winding current and is the winding resistance. Copper loss is directly proportional to the square of the load current; the larger the load, the greater the copper loss.

- Iron Loss: Iron loss, also known as no-load loss, refers to the loss generated in the core of a transformer under an alternating magnetic field during no-load operation. It mainly includes hysteresis loss and eddy current loss. Hysteresis loss is the loss generated by the repeated flipping of magnetic domains during alternating magnetization of the core material, and is related to the hysteresis loop area, magnetic flux density, and frequency of the core material. Eddy current loss is the loss generated by the induced current flowing inside the core under the action of an alternating magnetic field, and is related to the resistivity of the core material, the square of the magnetic flux density, the square of the frequency, and the square of the core thickness. Iron loss is independent of the load; it will occur whenever the transformer is connected to a power source.

- Efficiency: The efficiency of a transformer is calculated using the formula: , where is the output power, is the copper loss, and is the iron loss. Large medium and high voltage transformers typically have high efficiency, with an efficiency ≥98% under rated load and a Class I energy efficiency transformer ≥99%. Efficiency improvements are mainly achieved by reducing copper and iron losses, such as using high-grade silicon steel sheets, optimizing winding structure, and using oxygen-free copper rods.

2.2.3 Insulation performance

Insulation performance is a core safety performance indicator for large, medium, and high-voltage transformers, directly determining their service life and operational reliability. Large, medium, and high-voltage transformers operate at high voltage levels and experience large electric field strengths, thus imposing extremely stringent requirements on their insulation performance. Their insulation performance is primarily measured by the following indicators:

- Insulation Resistance: Insulation resistance refers to the resistance value of the insulating components of a transformer, reflecting the insulation performance of these components. The higher the insulation resistance, the better the insulation performance. The insulation resistance of large, medium, and high-voltage transformers mainly includes the winding-to-ground insulation resistance and the inter-winding insulation resistance, which are usually measured using a megohmmeter. The measured values should meet the relevant standard requirements.

- Dielectric Loss Factor: The dielectric loss factor refers to the ratio of active power loss to reactive power loss generated by the transformer insulation material under the action of an alternating electric field. It reflects the degree of insulation loss of the insulation material. The smaller the dielectric loss factor, the better the insulation performance. The dielectric loss factor of large medium and high voltage transformers is usually ≤0.005 (at 20℃). An excessively large dielectric loss factor will cause the insulation material to heat up and age, reduce insulation performance, and even cause insulation breakdown.

- Partial Discharge Level: Partial discharge refers to the partial discharge phenomenon that occurs under the influence of an electric field when there are defects inside the transformer insulation. Partial discharge accelerates the aging of insulation materials, reduces insulation performance, and long-term presence of partial discharge can lead to insulation breakdown. The requirements for partial discharge level of large medium and high voltage transformers are extremely stringent, typically requiring a partial discharge level ≤50pC, and some high-end products require ≤10pC.

- Withstand Voltage Strength: Withstand voltage strength refers to the maximum electric field strength that the insulation components of a transformer can withstand, reflecting the breakdown resistance of the insulation components. The withstand voltage strength of large medium and high voltage transformers mainly includes power frequency withstand voltage, lightning impulse withstand voltage, and switching impulse withstand voltage. During the withstand voltage test, the insulation components should be able to withstand the specified test voltage without breakdown, flashover, or other phenomena.

2.2.4 Short-circuit withstand capability

Short-circuit withstand capability is a crucial mechanical and electrical performance indicator for large, medium, and high-voltage transformers, reflecting their ability to withstand short-circuit faults. During operation, large, medium, and high-voltage transformers may experience winding short circuits, line short circuits, and other faults. Short circuits generate enormous short-circuit currents, which produce powerful electrodynamic forces that can lead to winding deformation, damage, or even transformer failure. Therefore, large, medium, and high-voltage transformers must possess excellent short-circuit withstand capability, which primarily includes dynamic stability and thermal stability.

- Dynamic Stability: Dynamic stability refers to the transformer’s ability to withstand the electrodynamic forces under short-circuit current without winding deformation or damage. The electrodynamic forces generated by short-circuit current are divided into axial and radial electrodynamic forces. Axial electrodynamic forces cause axial displacement and deformation of the windings, while radial electrodynamic forces cause radial expansion and deformation of the windings. Dynamic stability is mainly ensured through the winding structure design, material selection, and manufacturing process, such as using interlocked windings and strengthening the winding fixation.

- Thermal Stability: Thermal stability refers to a transformer’s ability to withstand the heat generated by a short-circuit current without causing aging or damage to the winding insulation. The heat generated by a short-circuit current causes a rapid increase in winding temperature. If the temperature is too high, it can lead to aging and breakdown of the winding insulation, or even burn out the winding. Thermal stability is mainly ensured through the selection of winding materials, cross-sectional dimensions, and cooling system design, such as using oxygen-free copper rods, increasing the winding cross-sectional dimensions, and employing a high-efficiency cooling system.

2.2.5 Temperature rise performance

Temperature rise performance is a crucial thermal performance indicator for large, medium, and high-voltage transformers, reflecting their heat dissipation capacity during operation. Transformers generate losses during operation, which are converted into heat, causing the temperature of various transformer components to rise. Excessive temperature rise accelerates the aging of insulation materials, reduces the transformer’s lifespan, and may even lead to transformer failure. Therefore, the temperature rise of large, medium, and high-voltage transformers must be controlled within specified limits.

The temperature rise of large medium- and high-voltage transformers mainly includes winding temperature rise, core temperature rise, and tank temperature rise, with winding temperature rise being the most critical control indicator. According to my country’s power industry standards, the winding temperature rise limit for oil-immersed large medium- and high-voltage transformers is 65K (55K for the top oil layer). For dry-type large medium- and high-voltage transformers, the winding temperature rise limit is determined based on the insulation class; for example, the limit is 100K for Class F insulation and 125K for Class H insulation. Temperature rise performance is primarily ensured through the design and manufacturing process of the cooling system, such as employing efficient cooling methods, optimizing the cooling system structure, and improving heat dissipation efficiency.

2.2.6 Voltage regulation performance

Voltage regulation performance is an important electrical performance indicator of large, medium, and high voltage transformers, reflecting the transformer’s ability to regulate output voltage. During operation, the grid voltage may fluctuate, and the load may change. In order to ensure the stability of the output voltage and meet the voltage requirements of electrical equipment, the transformer needs to have good voltage regulation performance.

The voltage regulation methods for large medium and high voltage transformers are mainly divided into two types: off-load voltage regulation and on-load voltage regulation. Off-load voltage regulation refers to adjusting the output voltage by changing the turns ratio of the windings when the transformer is de-energized. The regulation range is typically ±5% or ±2×2.5%. Off-load voltage regulating transformers have a simple structure and low cost, but voltage regulation is inconvenient. They are suitable for scenarios with small voltage fluctuations and minimal load changes. On-load voltage regulation refers to adjusting the output voltage by changing the turns ratio of the windings through an on-load tap changer when the transformer is energized. The regulation range is typically ±8×1.25% or ±10×1.25%. On-load voltage regulating transformers offer convenient and flexible voltage regulation, allowing for real-time adjustment of the output voltage. They are suitable for scenarios with large voltage fluctuations and significant load changes, such as main power grids and large industrial plants and mines.

2.2.7 Noise Level

Noise level is an important environmental performance indicator for large, medium, and high-voltage transformers, reflecting the magnitude of noise generated during transformer operation. During operation, large, medium, and high-voltage transformers generate noise from core vibration, winding vibration, and cooling system operation. Excessive noise can negatively impact the surrounding environment and people; therefore, it is necessary to control the transformer’s noise level.

The noise level of large medium and high voltage transformers is usually measured by the noise level under rated load, in dB(A). According to relevant standards, the noise level of large medium and high voltage transformers with voltage levels of 35kV~220kV is usually ≤75dB(A), and some high-end products require ≤70dB(A). Noise level control is mainly achieved through optimizing the core structure, adopting a low-noise cooling system, and strengthening vibration isolation.

2.3 Operating conditions and special requirements for large medium and high voltage transformers

2.3.1 Operating Condition Analysis

Large medium and high voltage transformers operate under complex and diverse conditions, influenced by various factors such as grid voltage, load changes, and environmental conditions. Their operating conditions can be mainly divided into three types: normal operating conditions, abnormal operating conditions, and fault operating conditions.

- Normal Operating Conditions: Normal operating conditions refer to the continuous operation of a transformer under rated voltage, rated frequency, and rated load. Under these conditions, the temperature, losses, voltage, current, and other parameters of all transformer components are within the specified range, and the operation is stable. Normal operating conditions are the most common operating conditions for large, medium, and high-voltage transformers and are also the main reference conditions during the design and manufacturing process.

- Abnormal Operating Conditions: Abnormal operating conditions refer to situations where, during transformer operation, some operating parameters exceed the normal range due to factors such as grid voltage fluctuations, load changes, and environmental condition variations, but no fault occurs. Common abnormal operating conditions include: excessively high or low voltage, overload, three-phase load imbalance, excessively high or low ambient temperature, and cooling system malfunctions. Abnormal operating conditions lead to increased transformer losses, higher temperature rise, and decreased insulation performance. Prolonged exposure to abnormal operating conditions accelerates transformer aging and reduces its service life. Therefore, timely measures are necessary to adjust operating parameters and restore normal operating conditions.

- Faulty Operating Conditions: Faulty operating conditions refer to situations where, during transformer operation, internal or external faults occur, causing operating parameters to significantly exceed normal ranges, or even preventing normal operation. Common internal faults include winding short circuits, core faults, and insulation breakdowns; common external faults include line short circuits, bushing faults, and lead wire faults. Faulty operating conditions can damage the transformer and even trigger large-scale power outages. Therefore, it is necessary to install comprehensive protection devices to promptly detect faults, disconnect power, and prevent the fault from escalating.

2.3.2 Special Operating Requirements

In light of the application scenarios and operating conditions of large medium and high voltage transformers, in addition to meeting basic performance requirements, they also need to meet the following special operating requirements:

- Severe Environmental Adaptability Requirements: Large medium and high voltage transformers are widely used in various harsh environments such as outdoor, high altitude, high humidity, salt spray, and extreme temperature and cold conditions, thus requiring excellent environmental adaptability. For example, low air pressure in high-altitude areas reduces insulation performance, necessitating enhanced insulation design; high humidity and salt spray areas are prone to corrosion, requiring the use of anti-corrosion materials and processes; and extreme temperature and cold regions experience large temperature variations, requiring transformers to start and operate normally under extreme temperatures.

- Renewable Energy Grid Connection Adaptation Requirements: With the development of the new energy industry, more and more large medium and high voltage transformers are being used for grid connection of new energy power plants such as photovoltaic, wind power, and energy storage. The operating conditions of new energy power plants are characterized by fluctuations and intermittency; therefore, transformers need to have good grid connection adaptation capabilities for new energy. For example, they need to have high overload capacity to withstand the fluctuating loads of new energy power generation; they need to have harmonic resistance to tolerate harmonic pollution generated by new energy power generation; and they need to have a wide voltage regulation range to adapt to voltage fluctuations in new energy power generation.

- Power Grid Stability Requirements: As core hub equipment in the power grid, the operational reliability of large medium- and high-voltage transformers directly affects the stability of the power grid. Therefore, they need to have good adaptability to power grid stability. For example, they need to have strong short-circuit withstand capability to withstand the huge electrodynamic forces generated by power grid short-circuit faults; they need to have good voltage regulation performance to adjust the output voltage in real time and maintain the stability of the power grid voltage; and they need to have rapid fault recovery capability to quickly restore normal operation after the fault is eliminated.

- Intelligent Operation and Maintenance Requirements: Large medium and high voltage transformers are bulky, heavy, and difficult to maintain, thus requiring robust intelligent operation and maintenance capabilities. For example, they need intelligent monitoring systems capable of real-time monitoring of transformer operating parameters and providing fault warnings; they need condition-based maintenance functions to rationally schedule maintenance plans based on the transformer’s operating status, reducing operation and maintenance costs; and they need remote monitoring capabilities to enable remote operation and maintenance.

- Energy Conservation and Consumption Reduction Requirements: Under the “dual carbon” target, energy conservation and consumption reduction have become an important development direction for large, medium, and high-voltage transformers, thus requiring excellent energy conservation and consumption reduction capabilities. For example, it is necessary to use low-loss core materials and winding materials to reduce the transformer’s no-load and load losses; it is necessary to adopt efficient cooling systems to improve heat dissipation efficiency and reduce cooling energy consumption; and it is necessary to optimize product design to achieve lightweighting and miniaturization, reducing transportation and installation energy consumption.

2.4 Chapter Summary

This chapter systematically reviews the relevant theoretical foundations of large, medium, and high-voltage transformers, clarifies their basic structure, working principle, core performance indicators, and analyzes their operating conditions and special requirements. Large, medium, and high-voltage transformers mainly consist of a core, windings, insulation system, cooling system, tank, leads, and accessories. Their working principle is based on the law of electromagnetic induction. Their core performance indicators include voltage level and rated capacity, losses and efficiency, insulation performance, short-circuit withstand capability, temperature rise performance, voltage regulation performance, and noise level. Operating conditions are categorized into normal operating conditions, abnormal operating conditions, and fault operating conditions. They also need to meet special requirements such as adaptability to harsh environments, compatibility with new energy grid integration, grid stability, intelligent operation and maintenance, and energy conservation and consumption reduction. This chapter lays a solid theoretical foundation for subsequent research on key technologies for the design and manufacture of large, medium, and high-voltage transformers.

3 Research on Core Design Technologies of Large Medium and High Voltage Transformers

The design of large, medium, and high-voltage transformers is a core guarantee of product performance, directly determining their reliability, energy efficiency, economy, and applicability. The design of large, medium, and high-voltage transformers involves multiple disciplines such as electromagnetics, heat transfer, materials science, and mechanical engineering. It requires comprehensive consideration of various factors, including voltage level, rated capacity, operating conditions, and special requirements, to achieve coordinated and optimized design of all components. This chapter focuses on the core design technologies of the core, windings, insulation system, and cooling system of large, medium, and high-voltage transformers, analyzes key influencing factors in the design process, and proposes targeted design optimization schemes to provide technical support for the design of large, medium, and high-voltage transformers.

3.1 Research on Iron Core Design Technology

The core is the magnetic circuit core of a large, medium, and high-voltage transformer, and its design quality directly affects the transformer’s no-load loss, excitation current, noise level, and mechanical strength. The core design of large, medium, and high-voltage transformers needs to balance requirements such as low loss, low noise, and high strength. Key design considerations include core material selection, core structure design, and core stacking process design.

3.1.1 Selection of Core Material

Core material is a key factor affecting the no-load loss and excitation current of transformers. Large medium and high voltage transformers primarily use grain-oriented silicon steel sheets for their cores. Grain-oriented silicon steel sheets have advantages such as high permeability, low loss, and high saturation magnetic flux density, which can effectively reduce the no-load loss and excitation current of transformers. When selecting grain-oriented silicon steel sheets, the following aspects need to be considered:

- Grade Selection: The grade of grain-oriented silicon steel sheets is mainly determined by their no-load loss and permeability. Higher grades generally indicate lower no-load loss and higher permeability. Large medium- and high-voltage transformers typically use high-grade grain-oriented silicon steel sheets for their cores, such as 30Q120, 27Q100, and 23Q090. The numerical part indicates the no-load loss value (unit: W/kg) under specific conditions; the smaller the number, the lower the no-load loss. For example, 30Q120 indicates a silicon steel sheet thickness of 0.30mm, with a no-load loss ≤1.20W/kg at a frequency of 50Hz and a magnetic flux density of 1.7T. When selecting a grade, it is necessary to comprehensively consider the transformer’s energy efficiency requirements and cost budget. Level 1 energy efficiency transformers typically use 27Q100 and higher grade silicon steel sheets, while Level 2 energy efficiency transformers can use grades such as 30Q120.

- Thickness Selection: The main thicknesses of grain-oriented silicon steel sheets are 0.23mm, 0.27mm, and 0.30mm. Thinner sheets result in lower eddy current losses and lower no-load losses, but also increase the processing difficulty and cost. Large medium- and high-voltage transformers typically use 0.27mm or 0.30mm thick silicon steel sheets for their cores, balancing no-load losses and processing costs. For high-end products with extremely high requirements for no-load losses, 0.23mm thick silicon steel sheets can be used.

- Performance Parameters: When selecting grain-oriented silicon steel sheets, it is also necessary to consider their performance parameters such as saturation magnetic flux density, permeability, and iron loss temperature coefficient. Higher saturation magnetic flux density results in a smaller core volume, enabling miniaturized transformer design; higher permeability leads to lower excitation current and lower reactive power losses; and a smaller iron loss temperature coefficient results in a smaller variation in no-load loss with temperature, leading to better operational stability of the transformer under different temperatures.

- Surface Coating: The surface of grain-oriented silicon steel sheets is usually coated with an insulating coating. The main function of the insulating coating is to isolate the silicon steel sheets, reduce eddy current losses, and protect the silicon steel sheets from oxidation and corrosion. When selecting the coating, it is necessary to consider its insulation performance, adhesion, heat resistance, etc., to ensure that the insulating coating does not peel off or become damaged during core stacking and operation.

Besides grain-oriented silicon steel sheets, amorphous alloy materials have also begun to be used in the core design of large medium and high voltage transformers in recent years. Amorphous alloy materials have extremely low no-load losses, which are only 1/3 to 1/5 of those of grain-oriented silicon steel sheets, significantly improving the energy-saving performance of transformers. However, amorphous alloy materials also have some disadvantages, such as lower magnetic permeability, higher excitation current, poorer mechanical strength, greater processing difficulty, and higher cost. Therefore, they are mainly used in scenarios with extremely high requirements for no-load losses, such as new energy power plants and main power grids.

3.1.2 Core Structure Design

The core structure of large medium and high voltage transformers mainly adopts a core-type structure, which is divided into single-phase core-type and three-phase core-type. Among them, the three-phase core-type structure is widely used in large medium and high voltage transformers due to its advantages such as compact structure, high material utilization rate, and good heat dissipation performance. The three-phase core-type iron core is mainly composed of iron core columns, yoke, clamping device, etc. The core design points include the cross-sectional design of the iron core column, the structural design of the yoke, and the design of the iron core joint.

- Core Column Cross-Section Design: The cross-sectional shape of the core column mainly includes circular, elliptical, and stepped shapes. Large medium and high voltage transformers typically use stepped cross-sections. Stepped cross-sections effectively reduce no-load losses and excitation current, improving core utilization. The number of steps in a stepped cross-section is usually 5 to 9. More steps result in a cross-section closer to a circle and lower no-load losses, but also increase manufacturing difficulty and cost. The selection of the number of steps requires comprehensive consideration of the transformer’s rated capacity, voltage level, and cost budget. Larger rated capacities and higher voltage levels require more steps. For example, transformers with a rated capacity of 10000kVA to 31500kVA typically use 5 to 7 steps in the core column cross-section; transformers above 31500kVA typically use 7 to 9 steps.

The cross-sectional area of the core column is mainly determined based on the transformer’s rated capacity, magnetic flux density, and frequency. The calculation formula is as follows:

Wherein, is the cross-sectional area of the iron core column (unit: m²), is the rated capacity of the transformer (unit: VA), is the power supply frequency (unit: Hz), is the number of winding turns, is the maximum magnetic flux density of the iron core (unit: T), and is the transformer efficiency.

The maximum magnetic flux density of the core of large medium and high voltage transformers is usually selected from 1.5 to 1.7T. If the magnetic flux density is too high, it will lead to increased no-load loss, increased excitation current, and even magnetic saturation. If the magnetic flux density is too low, it will lead to increased core volume, reduced material utilization, and increased cost.

- Yoke Structure Design: The main function of the yoke is to connect the core columns, forming a closed magnetic circuit. Its structural design directly affects the magnetic circuit performance and mechanical strength of the core. The yoke of large medium- and high-voltage transformers consists of an upper yoke and a lower yoke. The cross-sectional shape of the yoke is usually consistent with the cross-sectional shape of the core column, being a stepped shape. The cross-sectional area is usually equal to or slightly larger than that of the core column to ensure unobstructed magnetic circuitry and reduce magnetic reluctance and no-load losses.

The length of the yoke is mainly determined by the spacing and cross-sectional dimensions of the core posts. The spacing of the core posts is mainly determined by the winding diameter and insulation distance to ensure sufficient insulation distance between windings and between windings and the core, thus guaranteeing insulation performance. Simultaneously, the yoke is usually equipped with clamping devices to fix the core and prevent core vibration and deformation. The design of the clamping device needs to balance mechanical strength and insulation performance, avoiding any impact on the magnetic circuit.

- Core Joint Design: Core joints are weak points in the core magnetic circuit. High magnetic reluctance at the joints leads to increased no-load losses, higher excitation current, and increased noise. Therefore, the core joint design of large medium- and high-voltage transformers is crucial. Common joint types include mitered joints and direct joints. Misered joints are widely used in large medium- and high-voltage transformers due to their smooth magnetic circuit transition, low magnetic reluctance, and low no-load losses.

The angle of the miter joint is typically 45°, and the joint gap is usually controlled between 0.1 and 0.2 mm. Too large a gap will increase magnetic reluctance and no-load loss; too small a gap will cause friction between the silicon steel sheets, increasing processing difficulty and potentially affecting insulation performance. To further reduce no-load loss at the joint, a fully miter joint stacking method can be used, where the joints of adjacent silicon steel sheets are staggered to avoid joint concentration and make the magnetic circuit transition smoother.

- Core Grounding Design: During operation, the core of large medium and high voltage transformers generates induced voltage. If the core is not grounded or poorly grounded, this induced voltage can cause discharge between the core and other components, damaging the insulation. Therefore, a core grounding design is necessary. Large medium and high voltage transformers typically use a single-point grounding method, where the core is grounded to the tank via a grounding lead to ensure the core’s potential matches the tank’s, preventing induced voltage. The cross-sectional dimensions of the grounding lead need to be determined based on the magnitude of the induced current; copper or aluminum busbars are commonly used. Insulating sleeves must be installed at the grounding point to prevent short circuits between the grounding lead and other components.

3.1.3 Core Stacking Process Design

The core stacking process is a critical factor affecting core quality. For large medium- and high-voltage transformers, the core stacking process must ensure that the silicon steel sheets are stacked neatly, with tight joints and secure clamping, in order to reduce no-load losses, vibration, and noise. Key technological aspects include the selection of the stacking method, the design of the stacking sequence, and the control of clamping force.

The core differences between large medium- and high-voltage transformers (hereinafter referred to as large transformers) and ordinary transformers (hereinafter referred to as ordinary transformers, mostly low-voltage/small-capacity medium-voltage distribution transformers) lie in core dimensions such as voltage level, capacity, design process, performance requirements, and application scenarios. Furthermore, large transformers, due to their responsibility for supplying power to the main power grid and large loads, exhibit a much higher level of professionalism and complexity in manufacturing, installation, and operation and maintenance compared to ordinary transformers. The following is a clear comparison based on core dimensions, taking into account industry terminology and practicality, and adapting to the actual needs of transformer production and selection:

Core definition premise

First, clarify the conventional divisions within the industry; this is the foundation for distinguishing between the two:

Large medium and high voltage transformers: high voltage side voltage ≥35kV (core medium and high voltage section), rated capacity ≥10000kVA; if it is a 110kV/220kV high voltage section, the capacity is mostly ≥31500kVA, and they are mostly used for the main power grid and large-scale industrial/new energy supporting facilities.

Ordinary transformers: mainly 10kV/0.4kV low-voltage distribution transformers, with a small number of 20kV small-capacity medium-voltage transformers. The rated capacity is mostly in the range of 315kVA~2000kVA. They are the basic equipment at the end of the power distribution.

Large medium and high voltage transformers are key equipment in the power grid and are designed with redundancy (such as dual cooling, backup voltage regulating switches, and redundant monitoring sensors). They are required to have a mean time between failures (MTBF) of more than 20 years and need to be repaired quickly after a failure, otherwise it will cause regional power outages.

Ordinary transformers lack redundancy design, have an MTBF requirement of approximately 10-15 years, and can be directly replaced after a failure. The impact on power supply is limited to a small range of loads, and the replacement cost is low.

In short: ordinary transformers are “standardized power distribution consumables”, while large medium and high voltage transformers are “customized core equipment of power hubs”. The design, manufacturing and application logic of the two are completely different, which is also the core dividing mark between “civilian power distribution” and “industrial/grid-level power supply” in the transformer industry.